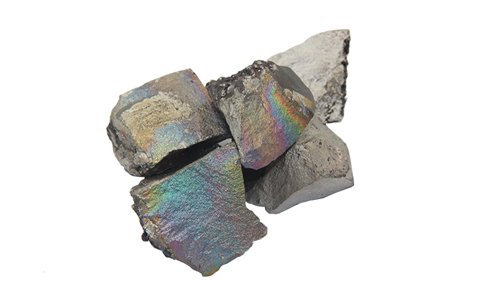

The role of silicon carbide in casting

Silicon carbide is an emerging non-metallic functional material, which has the advantages of high hardness, corrosion resistance, high temperature stability, good oxidation resistance, wear resistance, etc., so it is widely used in aviation, construction, machinery, electronics, chemical industry and other fields. Among them, the application of silicon carbide in the field of casting is increasing.